What is Fabricated sheet metal parts

Fabricated sheet metal parts are components that have been created through the process of sheet metal fabrication. This involves transforming flat metal sheets into desired shapes and structures for various applications across industries. These parts are used in a wide range of products, from everyday consumer goods to complex industrial machinery. Here’s a closer look at fabricated sheet metal parts:

Fabrication Process: Fabricated sheet metal parts are typically produced through a series of processes that include:

- Design: The process begins with the design of the sheet metal part using computer-aided design (CAD) software. The design determines the dimensions, shapes, and features of the final component.

- Material Selection: Based on the design’s requirements, the appropriate sheet metal material is chosen. Common materials include stainless steel, aluminum, carbon steel, and various alloys.

- Cutting: The chosen metal sheet is cut to the required dimensions using techniques like laser cutting, waterjet cutting, or CNC punching.

- Forming: The cut metal sheet is then shaped using processes like bending, rolling, and stamping to achieve the desired contours and dimensions.

- Joining: Different parts of the sheet metal are joined together using welding, brazing, or fasteners to create complex assemblies.

- Finishing: The fabricated parts undergo finishing processes such as sanding, deburring, and painting to improve aesthetics and remove sharp edges.

- Quality Control: Rigorous quality checks are performed at various stages to ensure the final parts meet design specifications and industry standards.

Applications: Fabricated sheet metal parts are used in a wide range of industries, including:

- Automotive: From car body panels to chassis components, fabricated sheet metal parts are essential for vehicles’ structure and functionality.

- Aerospace: Precision sheet metal parts are used in aircraft interiors, engine components, and structural elements.

- Construction: Sheet metal parts are used in architectural features, HVAC systems, and structural frameworks.

- Electronics: Enclosures, cabinets, and panels for electronic equipment are often made using sheet metal fabrication.

- Furniture: Sheet metal is used to create various components of furniture, such as frames and support structures.

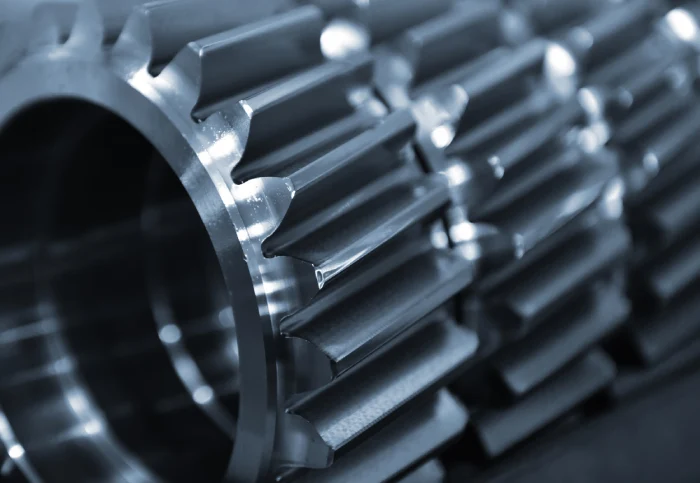

- Industrial Machinery: Fabricated sheet metal parts form the basis of many industrial machines and equipment.

- Consumer Goods: Household appliances, electronics, and kitchenware often contain sheet metal parts.

Advantages:

- Versatility: Sheet metal fabrication allows for the creation of diverse shapes and structures.

- Strength: Fabricated sheet metal parts can offer high tensile strength and durability.

- Cost-Effective: Bulk production of sheet metal parts can be cost-effective.

- Aesthetic Options: Sheet metal parts can be finished to enhance their appearance.